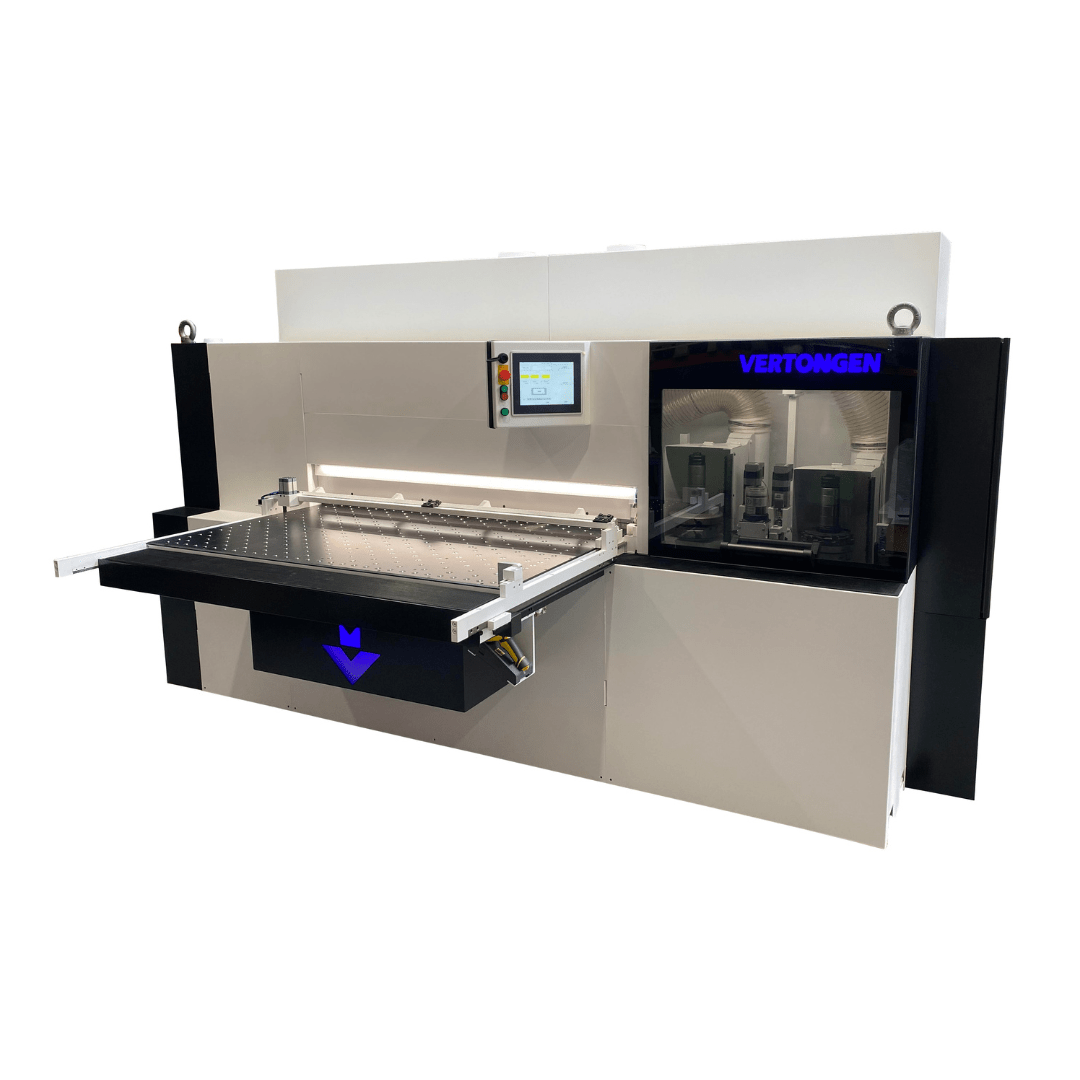

Shaper Sizer

The Shaper Sizer is a fully CNC-controlled woodworking machine. As implied by its name, it is built specifically for shaping, sizing, and squaring flat and elevated center panels and the outer edge profiles of assembled kitchen cabinet doors.

- Flat table, clamping the entire width

- From 4” to 60” in automatic mode

- Based on average door 16” by 24” = 300 parts / 8h

- Less sanding due to higher speed and bigger tooling

The Shaper Sizer is a fully CNC-controlled woodworking machine.

The high-end machine can simultaneously size, square, and shape, delivering rails that are coped and surfaced to final height and width.

Thanks to its two swiveling backstops on the automatic length-fence, CNC positioning of both table and spindles, and its electronically positioned clamping device over the total part width, the Shaper Sizer gets results accurate to the millimeter.

Technical product specifications

Spindle 1 + 2

- Motor:

- 7.5 kW (10HP) – 7200 RPM@60Hz

- Suspension:

- Dovetail

- Positioning:

- Horizontal +vertical CNC-positioned

- Horizontal pneumatic:

- On/Off for quick retraction

- Turning direction:

- Counterclockwise

- Movement:

- Vertical | 0mm - +270mm

- Spindle:

- 300 mm with Prolock, Ø 50 mm

- Tool Ø:

- Min. Ø 180 mm; max. Ø 240 mm (200mm advised)

- Dust extraction:

- Ø 180 mm

- Coping:

- 2 parts at the same time possible only with exactly the same height

- Oversize:

- Maximum 1.25”( for tooling with Ø 200 mm )

Spindle feed

- Construction:

- Both spindles installed on mobile unit that moves along the table

- Working speed:

- Adjustable 2-12m/min

- High speed:

- Vertical CNC-positioned clamp over the full width of the table

- Lubrication:

- Automatic lubrication system

- Oversize:

- Electronical oversize surveillance for entering parts

Table

- Construction:

- Fixed stable air jet table

- Safety specification:

- Pneumatic clamp for straight backing wood

- Clamping:

- Vertical CNC-positioned clamp over full width of the table

- Length-fence:

- Automatic with 1 large pneumatic swiveling back stop and 1 manual swiveling backstop

- Part length:

- Minimum 4.0” and maximum 62”

- Part width:

- Minimum 4”(1,5 for coping) and maximum 62”

- Table dimensions:

- 62” x 40”(useful)

You may also be interested in

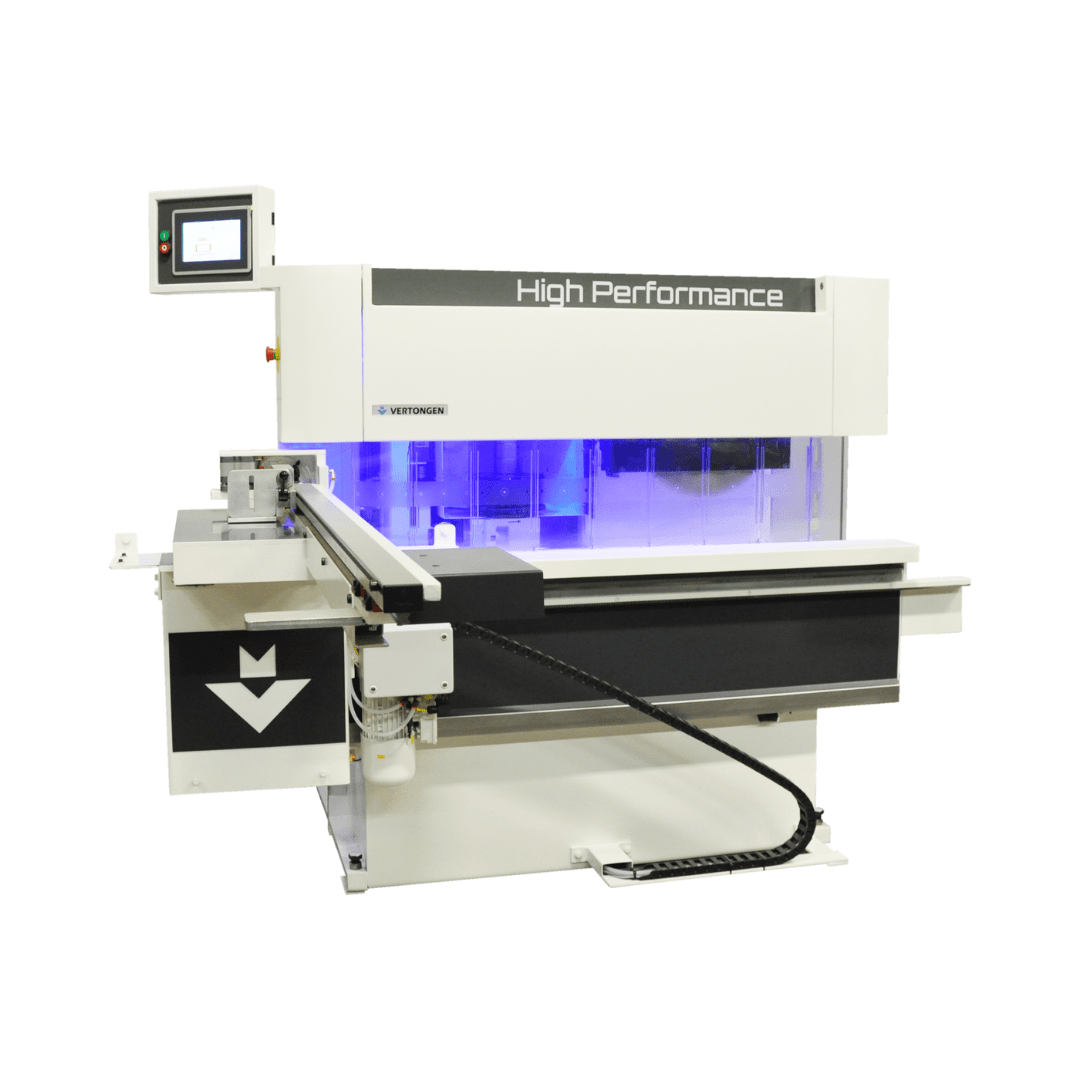

Pentho Compact Kitchen

The Pentho Compact Kitchen is our smart tenoner. Its spindle is designed to stack tools. Allowing you to size and cope your rails and stiles without manual setup between different profiles.

- Saw with a cut-off capacity of 1.25″

- 1 x Vertical spindle 300 mm with Prolock

- 7” touch panel for starting motors and job recipes in own language

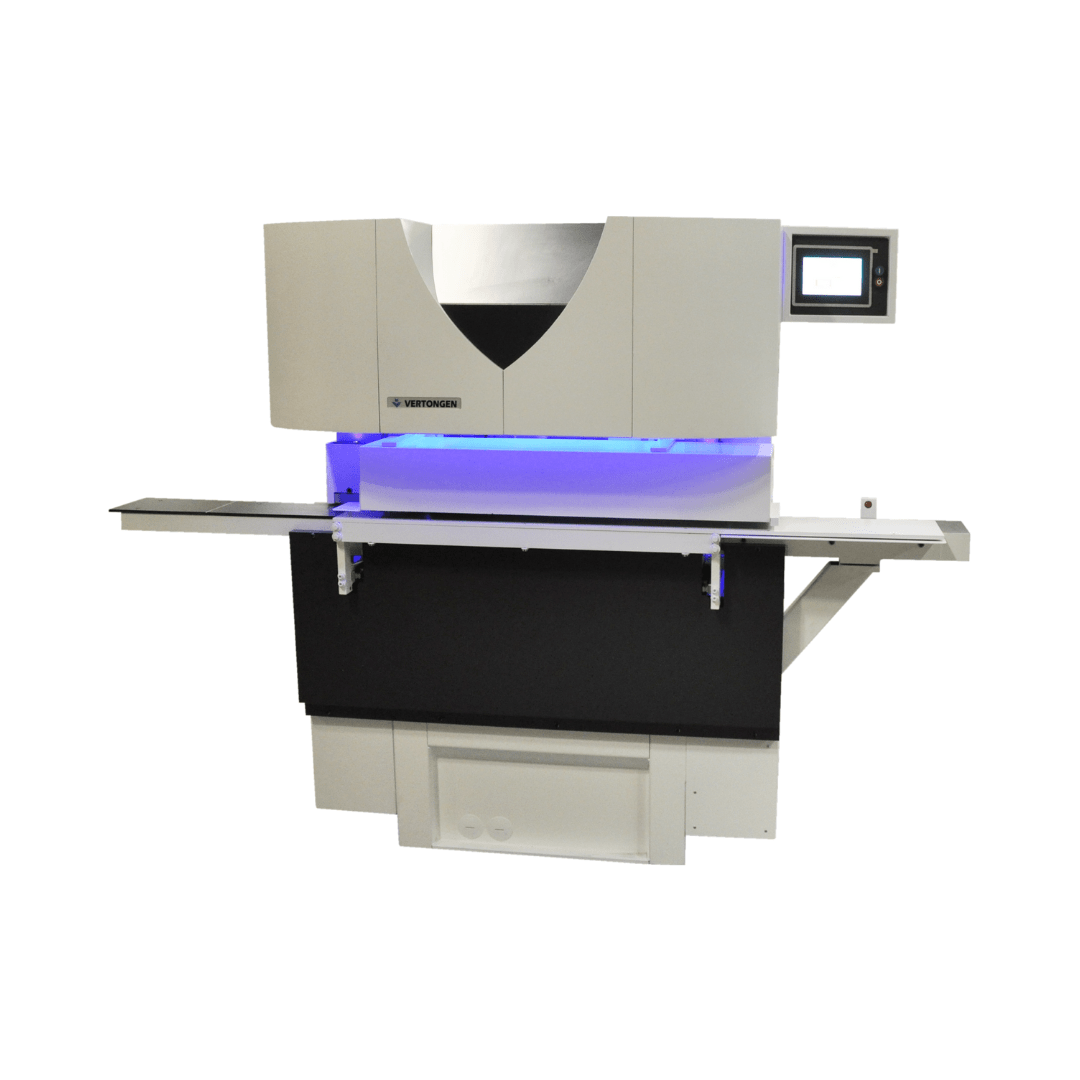

Profil Compact Kitchen

The Profil Compact Kitchen is our intelligent profile moulder. Its spindle is designed to stack tools. The machine allows you to stick your rails and stiles, without manual set-up between different profiles.

- No manual setup between different profiles

- 7 inch touch panel in own language

- Integrated feeding device

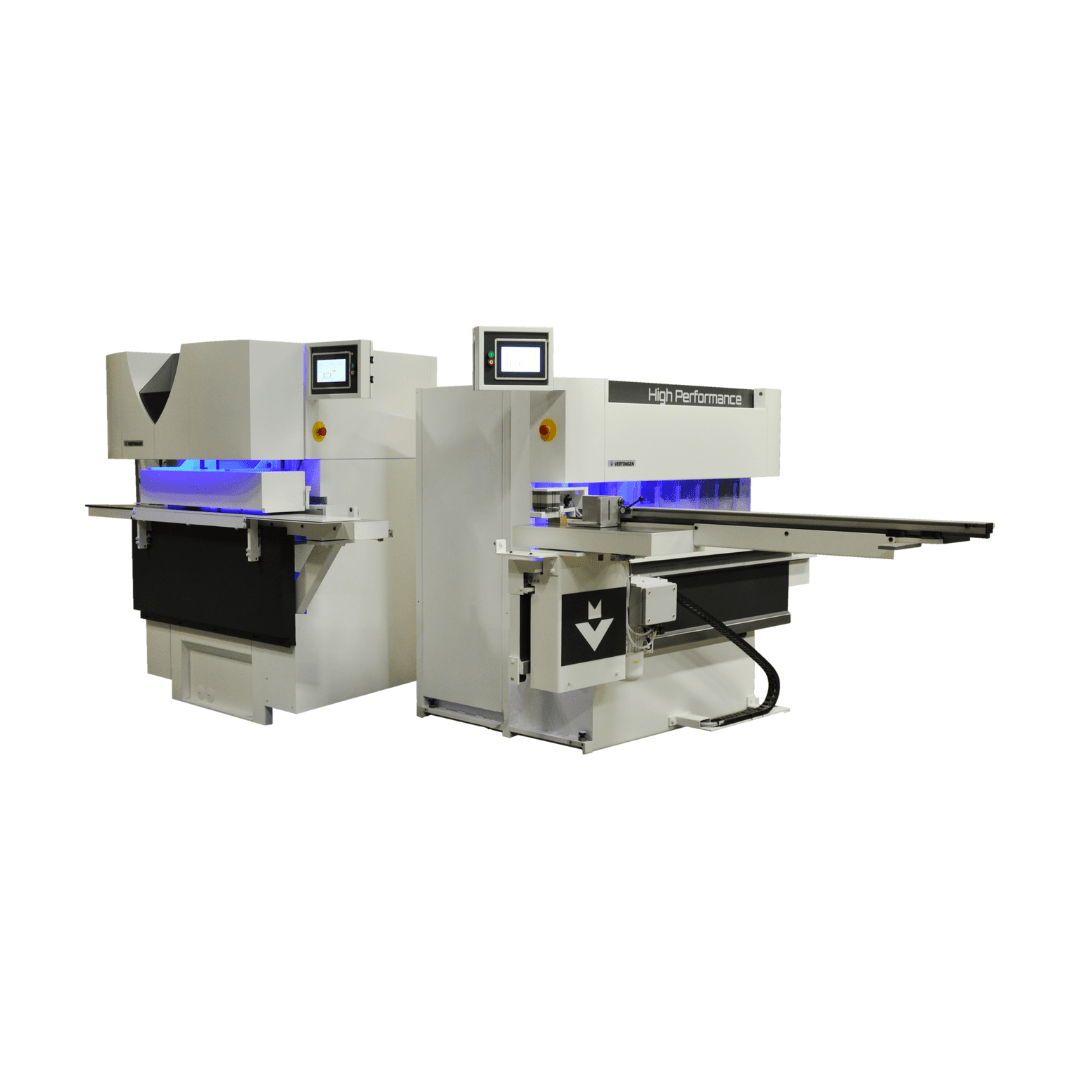

PenPro Compact Kitchen

The PenPro Compact Kitchen is our complete solution. One operator can work simultaneously with two pieces, producing complete kitchen cabinet door frames with the highest efficiency and accuracy.

- 1 unit for both cope and stick joints

- Batch size 1 or mass-production (400 to 800 doors/ 8-hour shift) of highly customized products

- 1 operator

- From lengths of 4″ up to 100″ and widths of 1,5″ up to 9″

Please fill out the form below and you will receive a link via email to download our brochure.

Find a Vertongen dealer

Vertongen is a Belgium-based company with distributors all over the world. All of them are knowledgeable about the operation and use of our machines.

Want to know more about Vertongen, our machines, how they work, and how to implement them into your operations?

Contact us and get ready to revolutionize your production process or contact a local supplier.