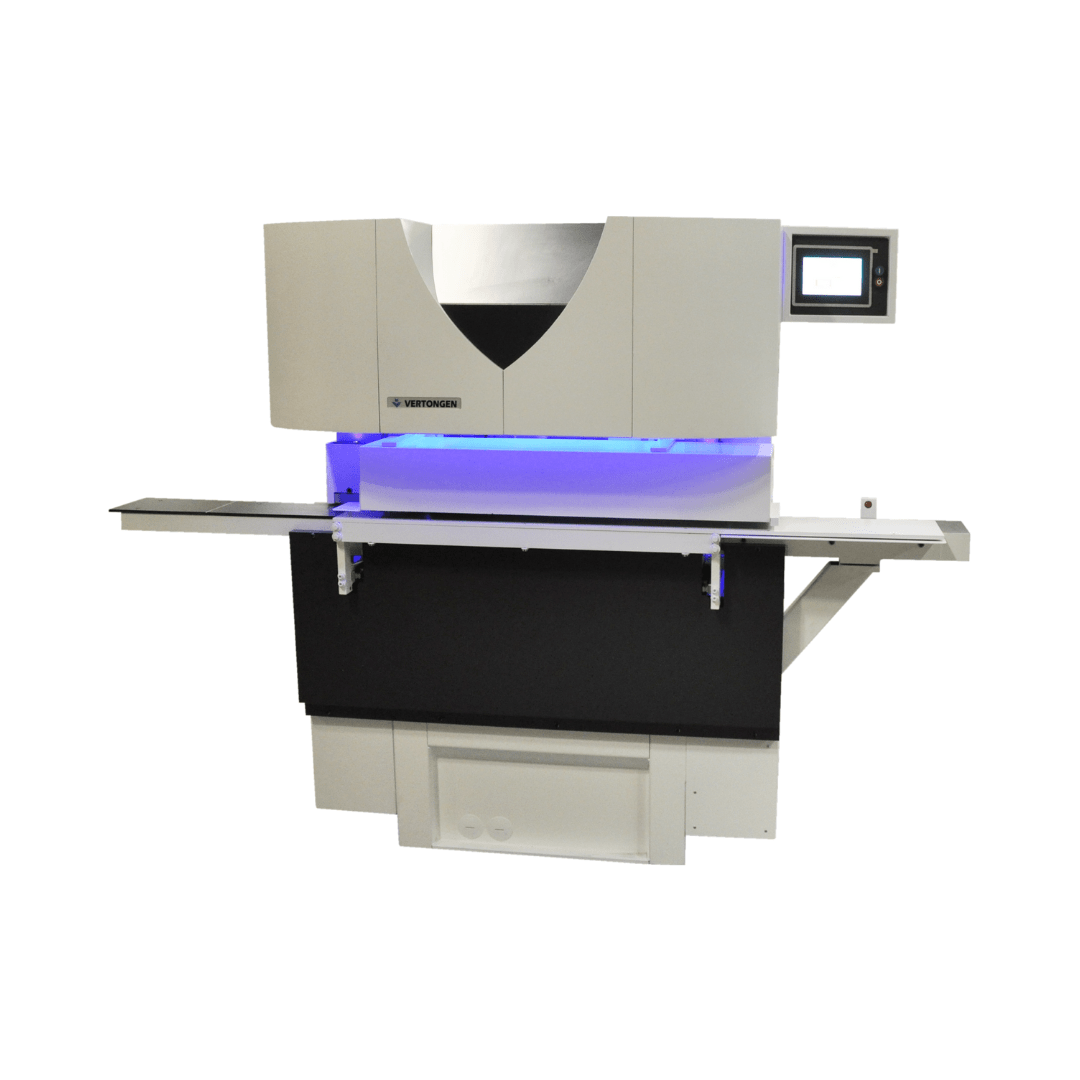

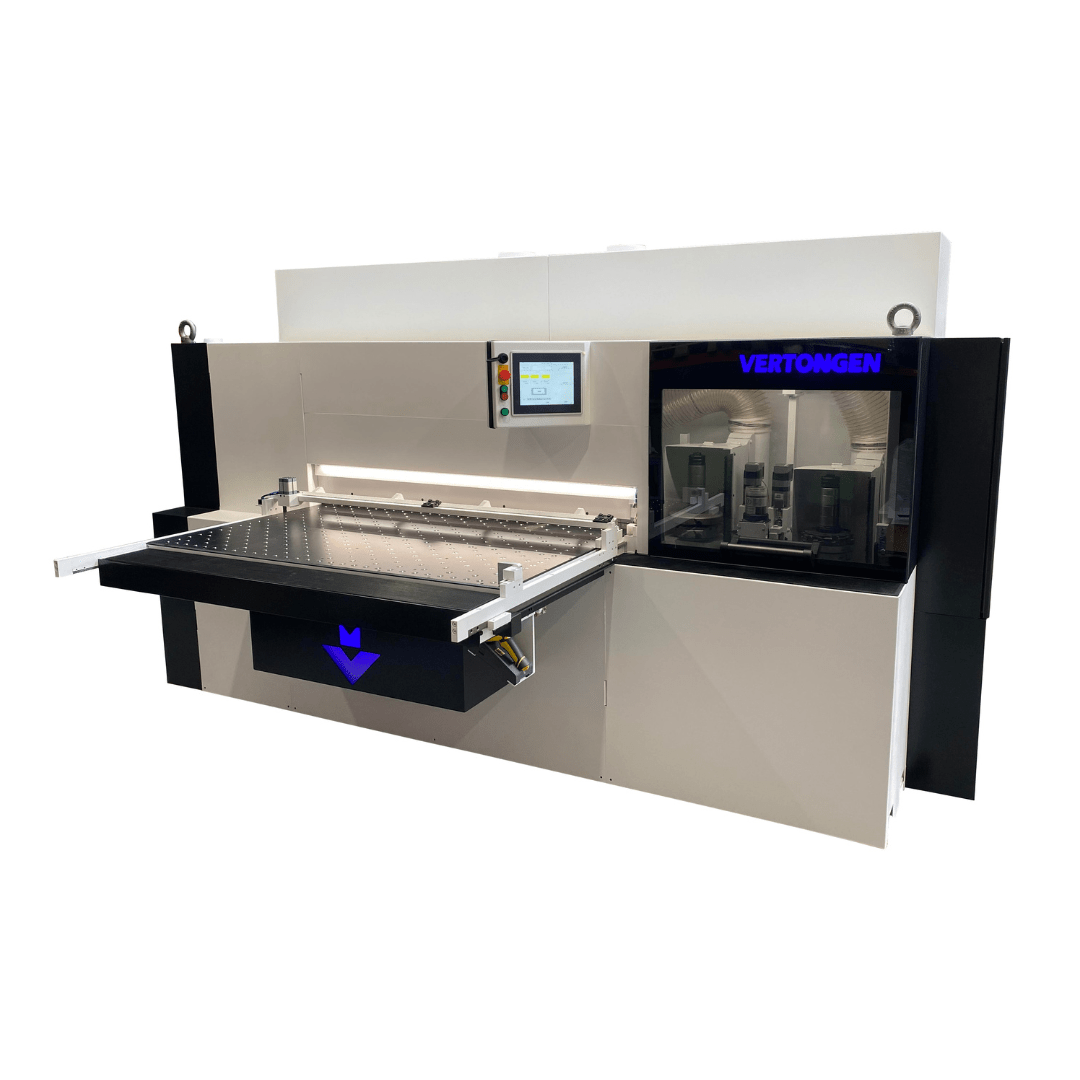

Profil Compact Kitchen

The Profil Compact Kitchen is a fully CNC-controlled moulder with one vertical Prolock spindle of 300mm.

- One vertical spindle 300mm

- CNC-controlled moulder

- No manual setup between different profiles

- 7 inch touch panel in own language

- Integrated feeding device

The Profil Compact Kitchen is a fully CNC-controlled moulder with one vertical Prolock spindle of 300mm.

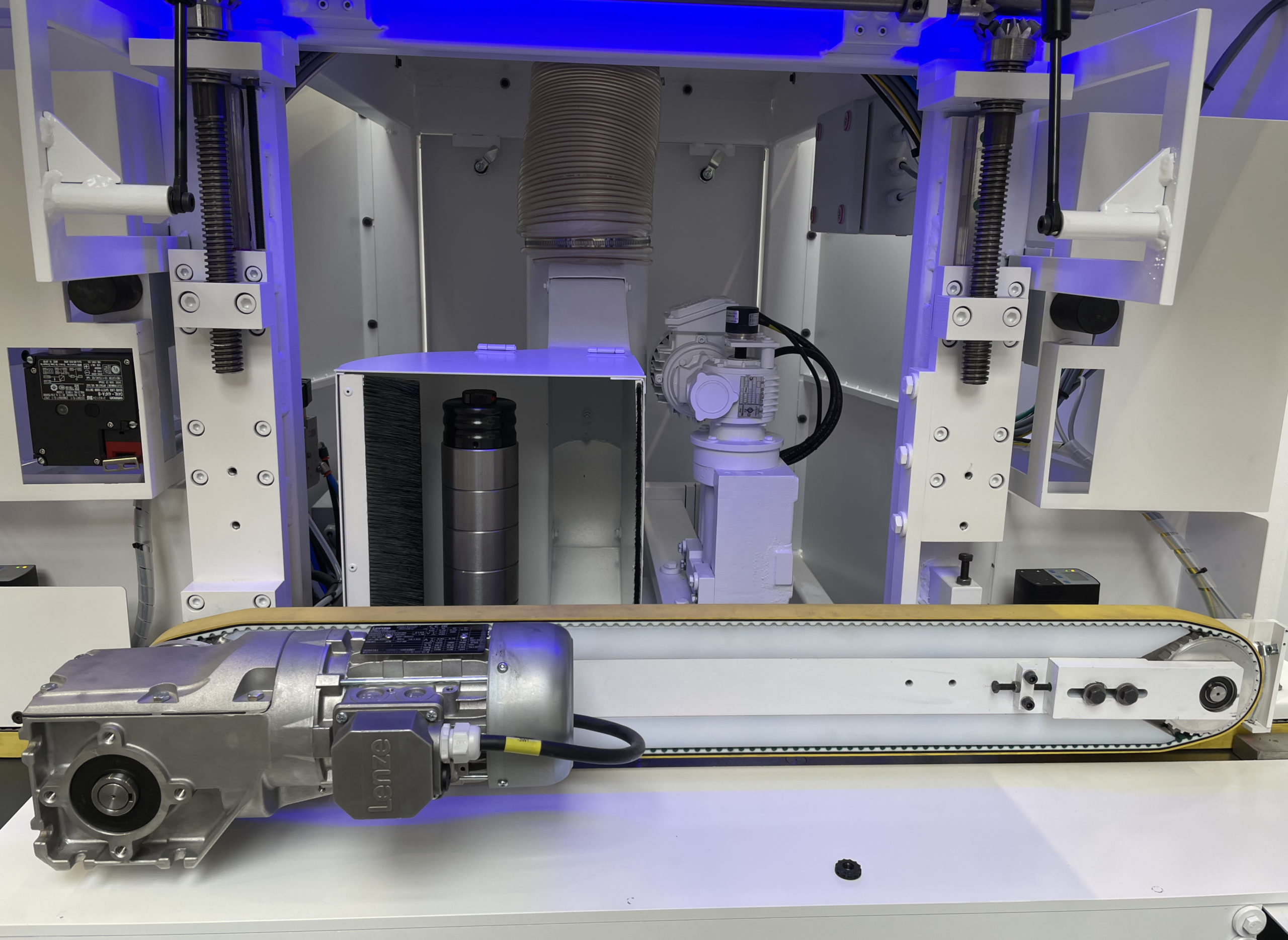

The spindle is designed to stack tools, allowing you to machine different varieties of kitchen cabinet door profile “stickings”, without manual set-up between different profiles. The solid steel table, and cutout for the vertical spindle profile, contribute to exact accuracy. While Air jets in the table create an air cushion between the workpiece and the machine surface for better through-feed. And the automatic outside fence allows you to smoothly change-over in between parts of different widths.

Vertongen tip!

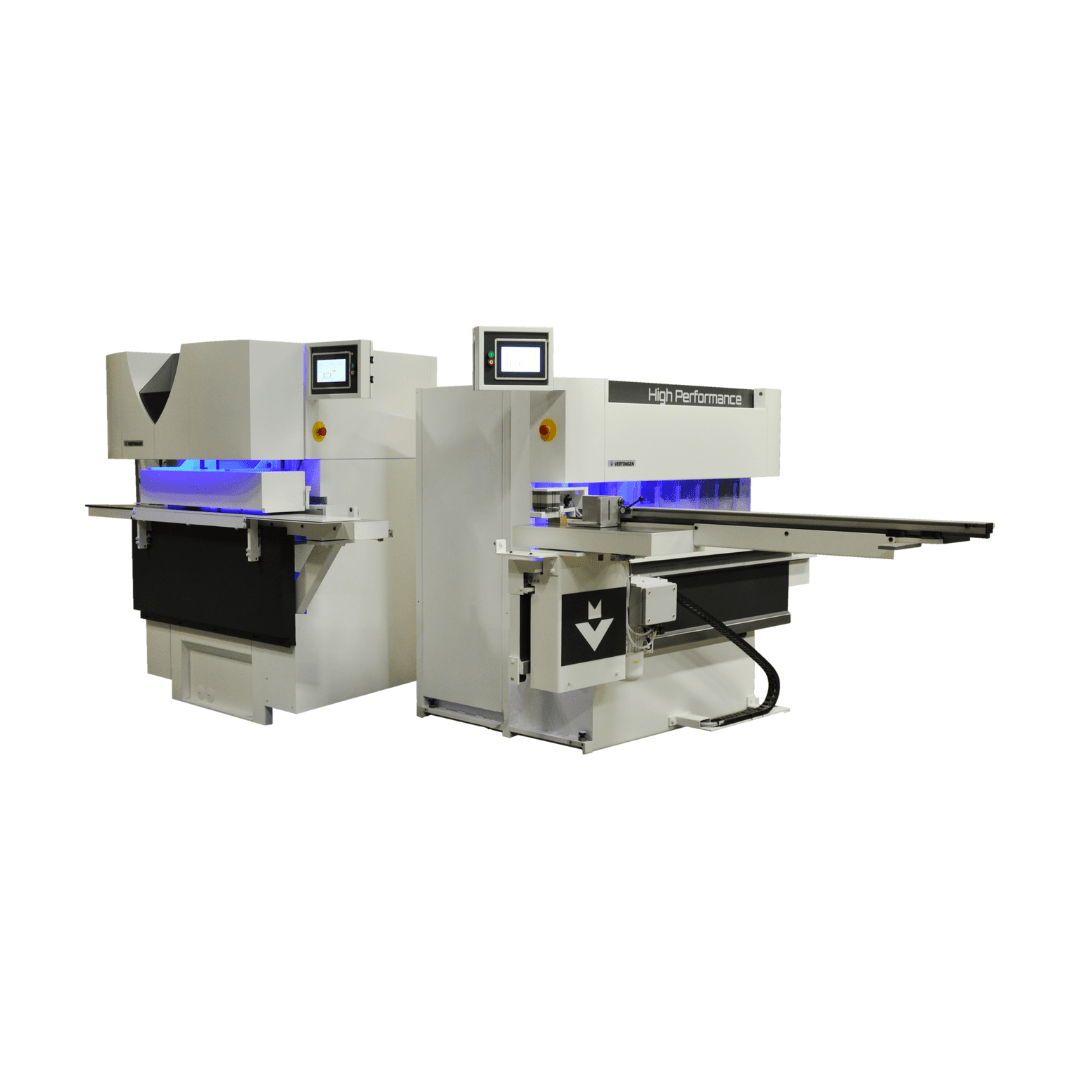

Combine the Profil Compact Kitchen with the Pentho Compact Kitchen for complete production of kitchen cabinet door frames.

Technical product specifications

Vertical Spindle

- Motor:

- 7.5 kW (10HP) – 7200 RPM@60Hz

- Suspension:

- Dove tail

- Positioning:

- Vertical cnc-positioned, horizontal Fix

- Turning direction:

- Counter clockwise

- Spindle:

- 300 mm with Prolock, Ø 50 mm

- Tool:

- Min Ø 160 mm; max. 240 mm

- Extraction:

- 180 mm diameter

Table

- Guiding:

- Outside fence cnc-positioned

- System:

- Through feed

Feed Device

- Speed:

- Adjustable between 2 – 12 m/min

- Feeding type:

- Top belt, minimum part length 4 inch

- Part Thickness:

- Min. 0.6” to max. 1.25”

- Part Width:

- Min. 1.5” to max. 9”

- Max. profile depth:

- 0.75”

- Part tolerance in height:

- Maximum 0.004” / 0.1 mm

- Part oversize in width:

- Between 0.00” and 0.0625”

Chassis

- Safety specification:

- CE

- Dimensions:

- 2300 x 1380 x 1800 mm ( L x W x H ) / Weight: 1200 kg (2650 lbs)

- Total extraction:

- 1 x Ø 180 mm

Controller

- Touch panel:

- 7” touch screen at eye level

- Motors:

- All motors are started via control panel

- Touch panel:

- Memory for saving programs for easy call-up and repeatability

- Programming:

- Programming via Teach-in command for creation of new profiles

Power / electrics / compressed air

- Electrics:

- 400V 3 phase + Neutral + Ground / Amperage: 20A (@ 400V)

- Transformer:

- Transformer included with machine for customers voltage (230V, 460V or 480V)

- Certification:

- Electrical cabinet CSA/UL-Certified

- Compressed air:

- 1000NL/min; 6 bar

You may also be interested in

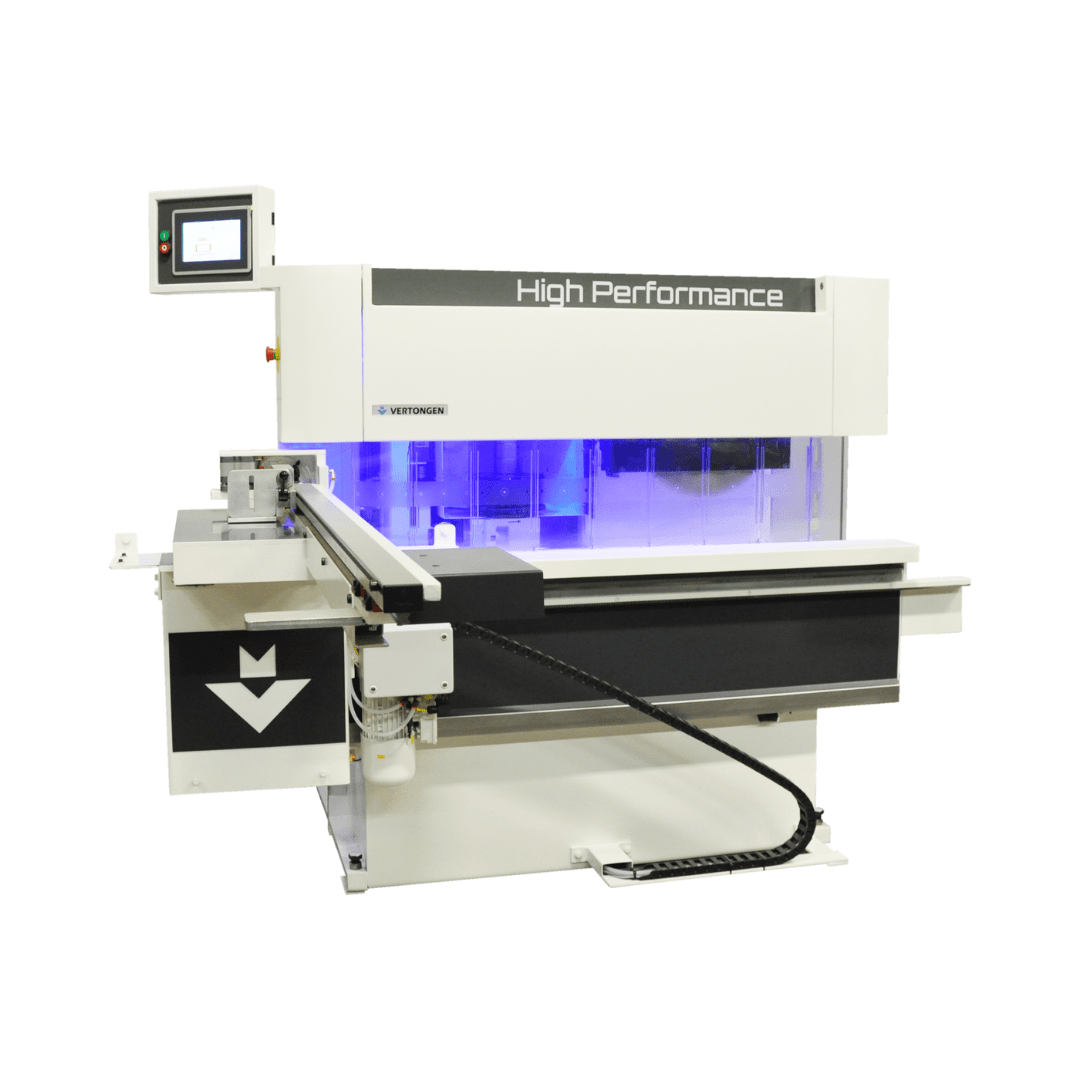

Pentho Compact Kitchen

The Pentho Compact Kitchen is our smart tenoner. Its spindle is designed to stack tools. Allowing you to size and cope your rails and stiles without manual setup between different profiles.

- Saw with a cut-off capacity of 1.25″

- 1 x Vertical spindle 300 mm with Prolock

- 7” touch panel for starting motors and job recipes in own language

PenPro Compact Kitchen

The PenPro Compact Kitchen is our complete solution. One operator can work simultaneously with two pieces, producing complete kitchen cabinet door frames with the highest efficiency and accuracy.

- 1 unit for both cope and stick joints

- Batch size 1 or mass-production (400 to 800 doors/ 8-hour shift) of highly customized products

- 1 operator

- From lengths of 4″ up to 100″ and widths of 1,5″ up to 9″

Shaper Sizer

The Shaper Sizer is specifically designed for shaping, sizing, and squaring flat and raised center panels as well as the outer edge profiles of assembled kitchen cabinet doors. It’s also able to cope and size the rails that are surfaced to final height and width.

By CNC-positioning of the spindles, the Shaper Sizer works highly accurate. Saving you a lot of time and rework.

- Flat table, clamping entire width

- From 4″ up to 60″ in automatic mode

- Less sanding due to higher speed and bigger tooling

Please fill out the form below and you will receive a link via email to download our brochure.

Find a Vertongen dealer

Vertongen is a Belgium-based company with distributors all over the world. All of them are knowledgeable about the operation and use of our machines.

Want to know more about Vertongen, our machines, how they work, and how to implement them into your operations?

Contact us and get ready to revolutionize your production process or contact a local supplier.