The Vertongen kitchen cabinet door unit enables you to:

Save on space

Save on inventory

Save on time

As a kitchen cabinet door manufacturer, your floor is filled with several machines.

Each machine covers a different step of the production process. And each machine is operated by a different person. Therefore, no matter how professional your employees are, errors and inaccuracies in the final products are almost inevitable. This not only costs you time but also money in mechanical adjustments.

Why don’t you improve and upscale your production with one integrated solution?

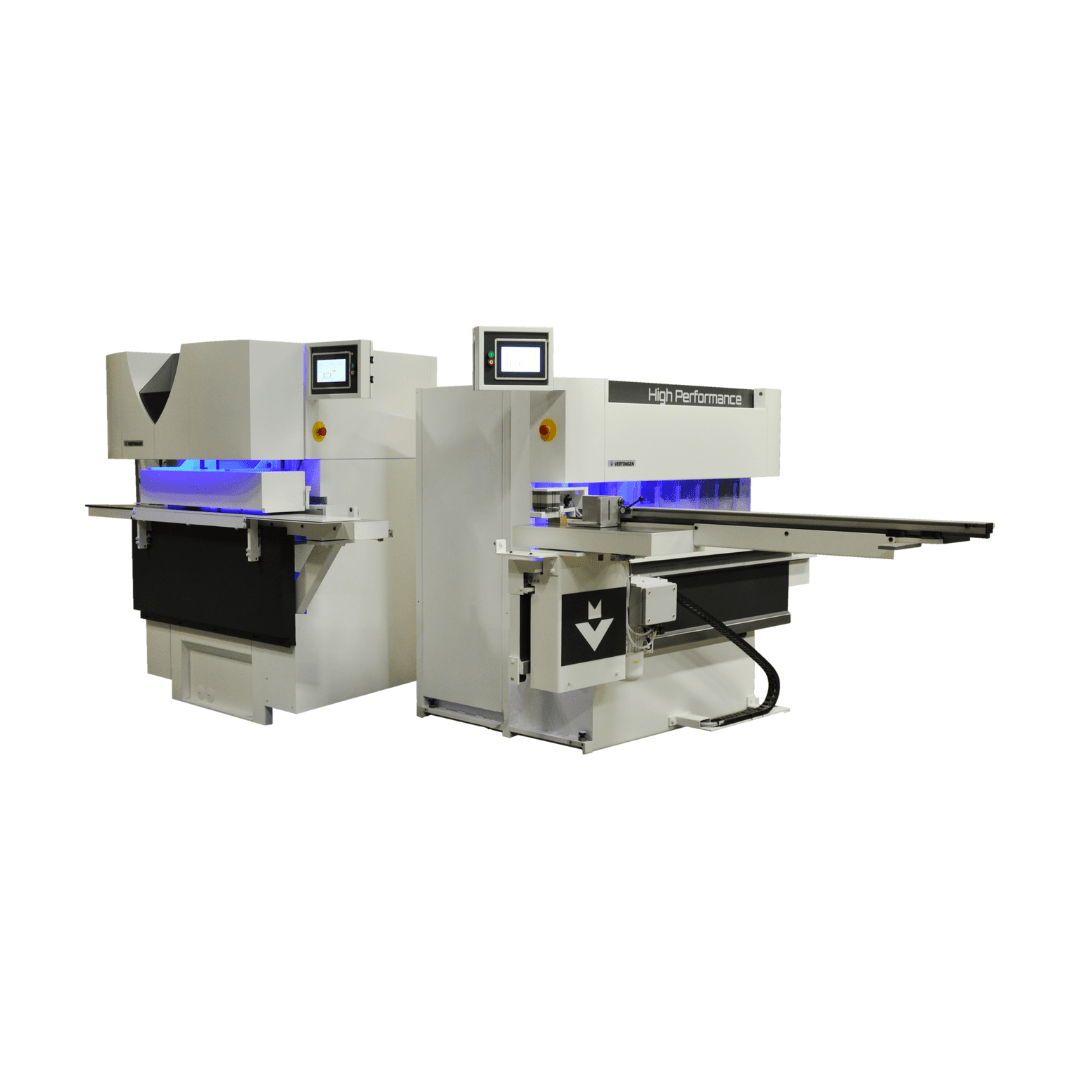

Where you now need multiple machines, the PenPro Compact Kitchen and the Shaper Sizer cover the entire range. These devices work extremely accurately and only require one person to operate them.

Why choose Vertongen?

Thanks to our continuous focus on the market and the cooperation with Stiles Machinery we deliver top quality machines tailored to the specific production of the 5- piece kitchen cabinet door.

Our fully CNC-controlled assets:

Highly accurate. No rework,

right from the first time.

Barcode system

with CSV-data.

2 units for 99% of

general production.

Pentho Compact Kitchen

The Pentho Compact Kitchen is our smart tenoner. Its spindle is designed to stack tools. Allowing you to size and cope your rails and stiles without manual setup between different profiles.

- Saw with a cut-off capacity of 1.25″

- 1 x Vertical spindle 300 mm with Prolock

- 7” touch panel for starting motors and job recipes in own language

Profil Compact Kitchen

The Profil Compact Kitchen is our intelligent profile moulder. Its spindle is designed to stack tools. The machine allows you to stick your rails and stiles, without manual set-up between different profiles.

- No manual setup between different profiles

- 7 inch touch panel in own language

- Integrated feeding device

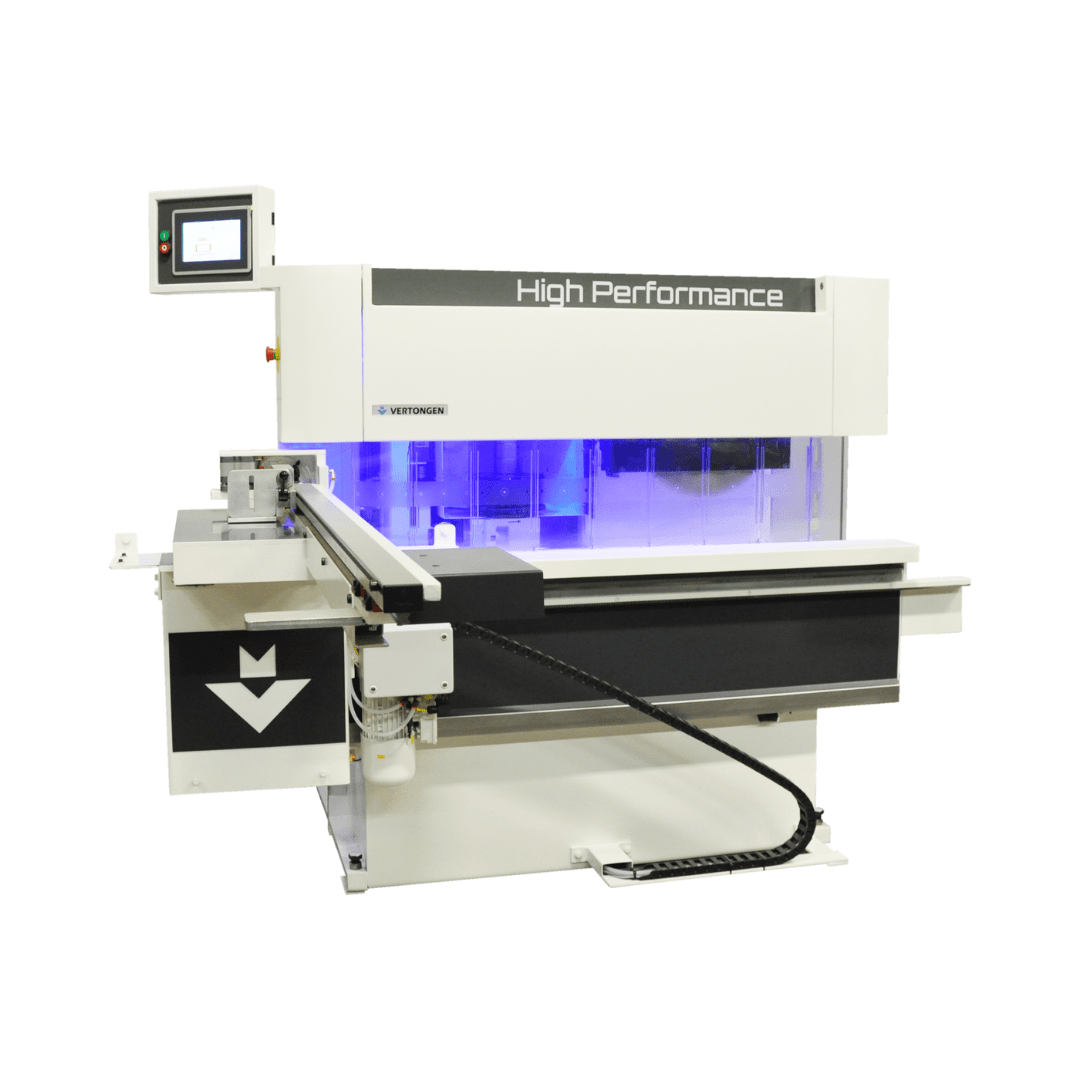

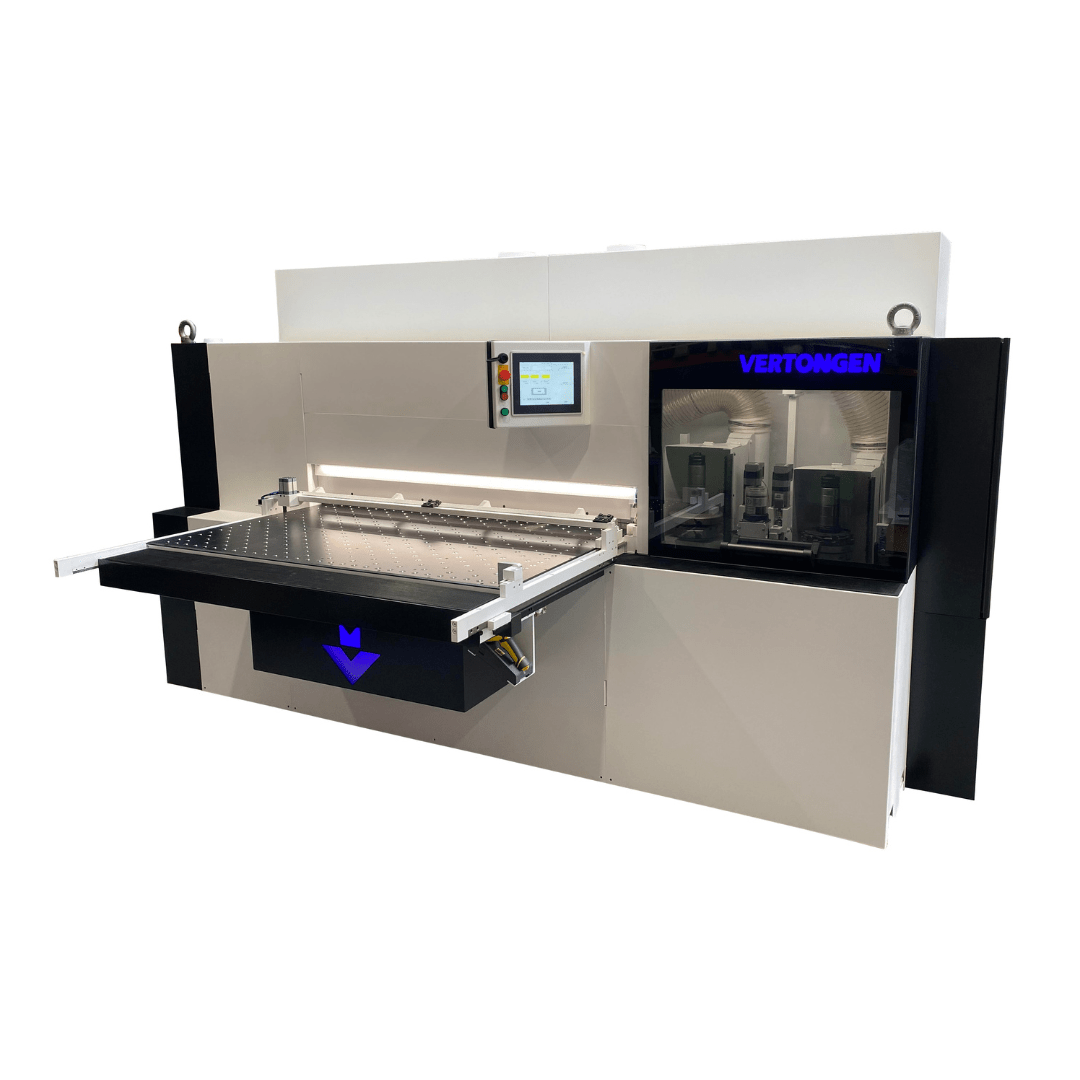

PenPro Compact Kitchen

The PenPro Compact Kitchen is our complete solution. One operator can work simultaneously with two pieces, producing complete kitchen cabinet door frames with the highest efficiency and accuracy.

- 1 unit for both cope and stick joints

- Batch size 1 or mass-production (400 to 800 doors/ 8-hour shift) of highly customized products

- 1 operator

- From lengths of 4″ up to 100″ and widths of 1,5″ up to 9″

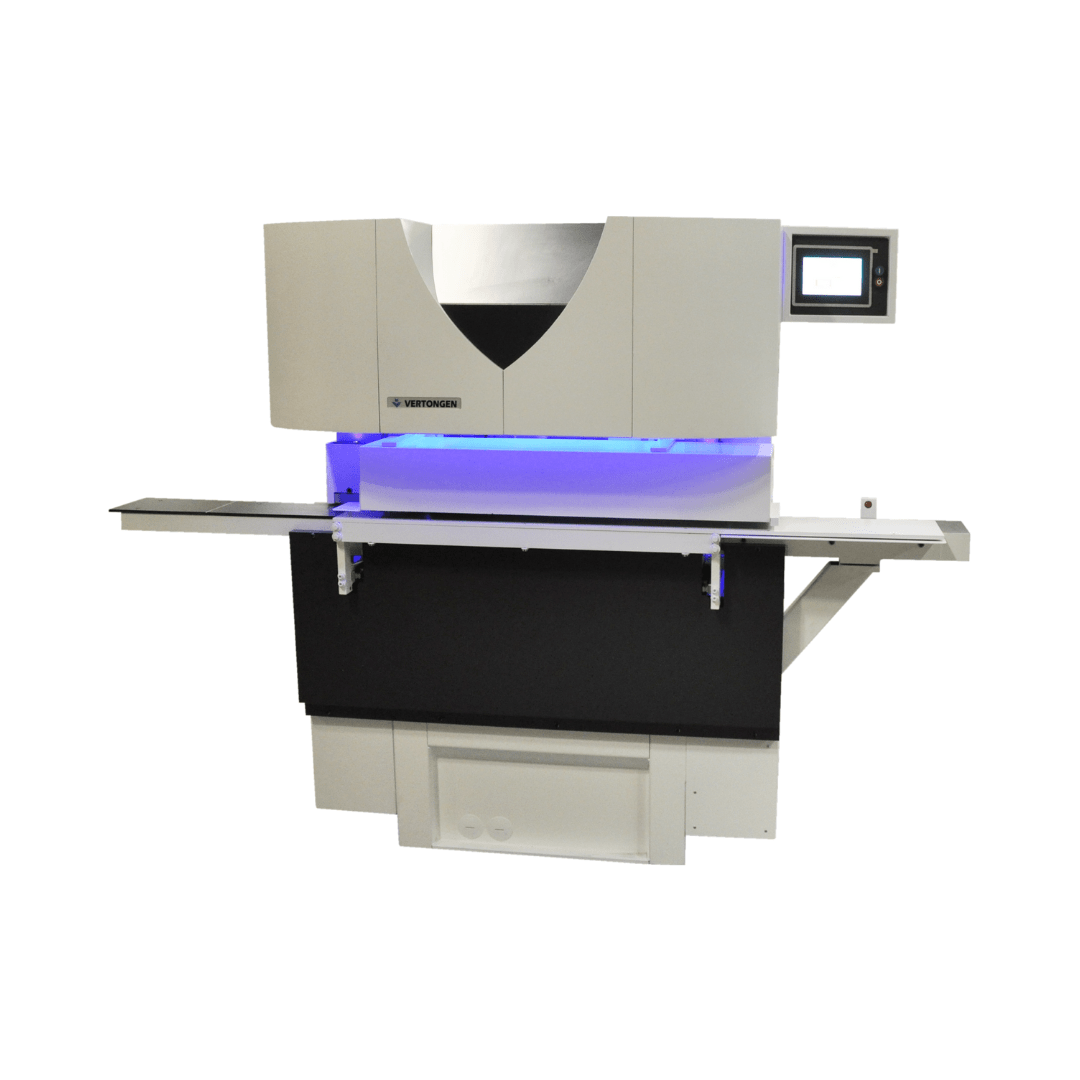

Shaper Sizer

The Shaper Sizer is specifically designed for shaping, sizing, and squaring flat and raised center panels as well as the outer edge profiles of assembled kitchen cabinet doors. It’s also able to cope and size the rails that are surfaced to final height and width.

By CNC-positioning of the spindles, the Shaper Sizer works highly accurate. Saving you a lot of time and rework.

- Flat table, clamping entire width

- From 4″ up to 60″ in automatic mode

- Less sanding due to higher speed and bigger tooling

Are your current woodworking machines

in need of replacement?

Opt for a smart upgrade of your production equipment. Trade in your outdated machine park for a single Vertongen unit. More information? Get in touch with our experts. They know your challenges and will help you scale up your business.

Find us in the US

With Vertongen, Stiles Machinery has found the right partner to sell a solution for the production of 5-piece kitchen cabinet doors. We offer the PenPro Compact Kitchen as an integrated production cell together with the Shaper Sizer. Offering a product that is revolutionary and affordable at the same time. We have accomplished a strong market position in a market where previous solutions were too expensive to bypass manual work.

We make automated, professional machinery accessible for all kitchen cabinet door manufacturers.

You want a Stiles expert to contact you and help you grow your business by making your workspace more efficient and effective?

Fill in the form and we’ll get in touch to make an appointment. A Stiles Machinery expert is coming over and makes an offer tailored to your business needs.

Alternatively, you can reach us by phone: 1-616-698-7500