The future of tenoners is here

Our tenoners help you make quick, high-quality work of complex slot and tenon joinery. The high-end machinery is suitable for the most professional craftsmen and workplaces.

Pentho Compact 3

The Pentho Compact 3 is our universal tenoner. It has a noise-reduced cut-off saw, two tenon heads and a vertical Prolock spindle adjustable to an accuracy of 0.1 mm.

- All movements are manual adjustable

- 7” touch panel for starting motors and job recipes in own language

- Total table swiveling +60° / -60°

- Round backing wood available

- Digital length-fence 2.4 with 1 swiveling backstop

- High-quality saw and tenon heads installed

Convert your set-up time into valuable production time

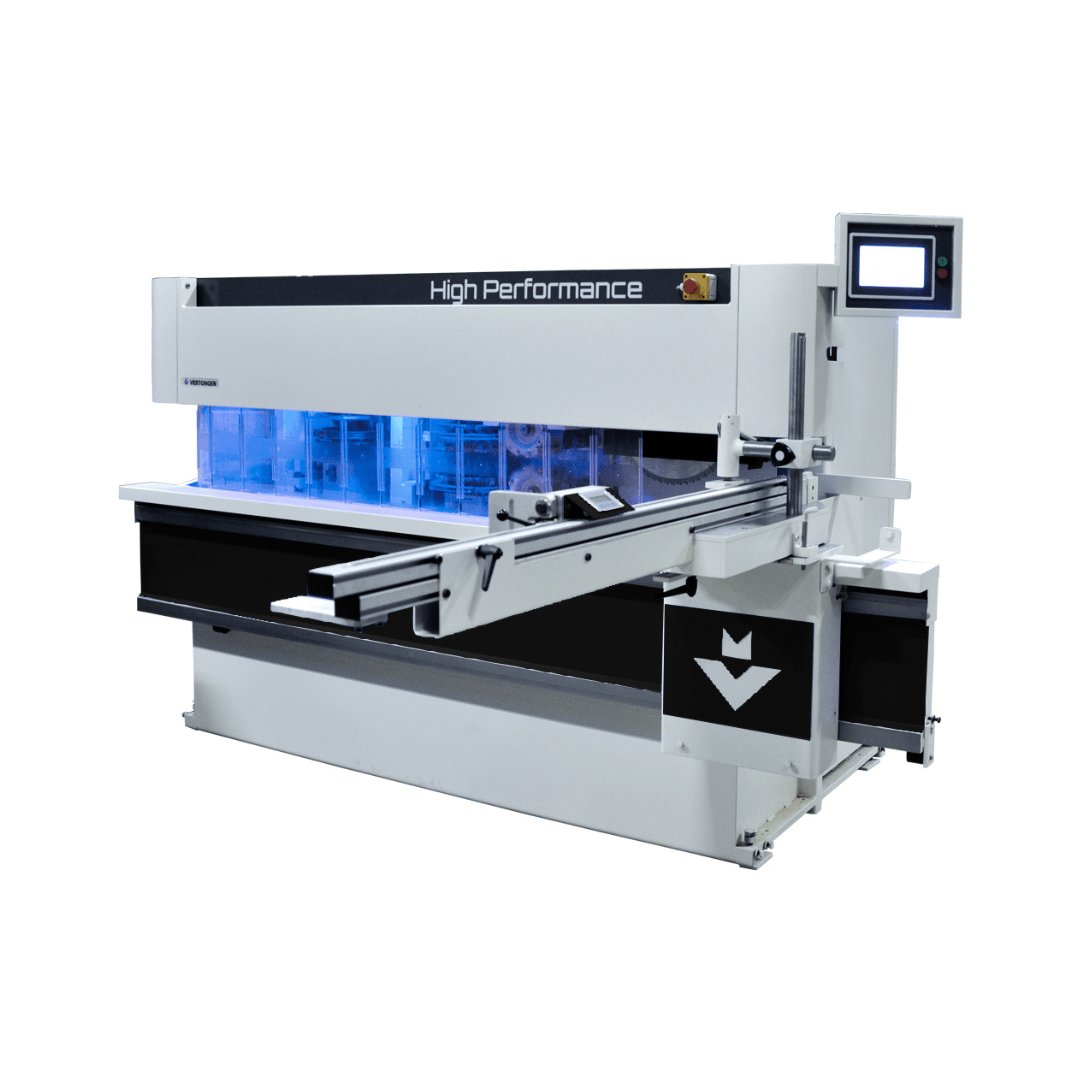

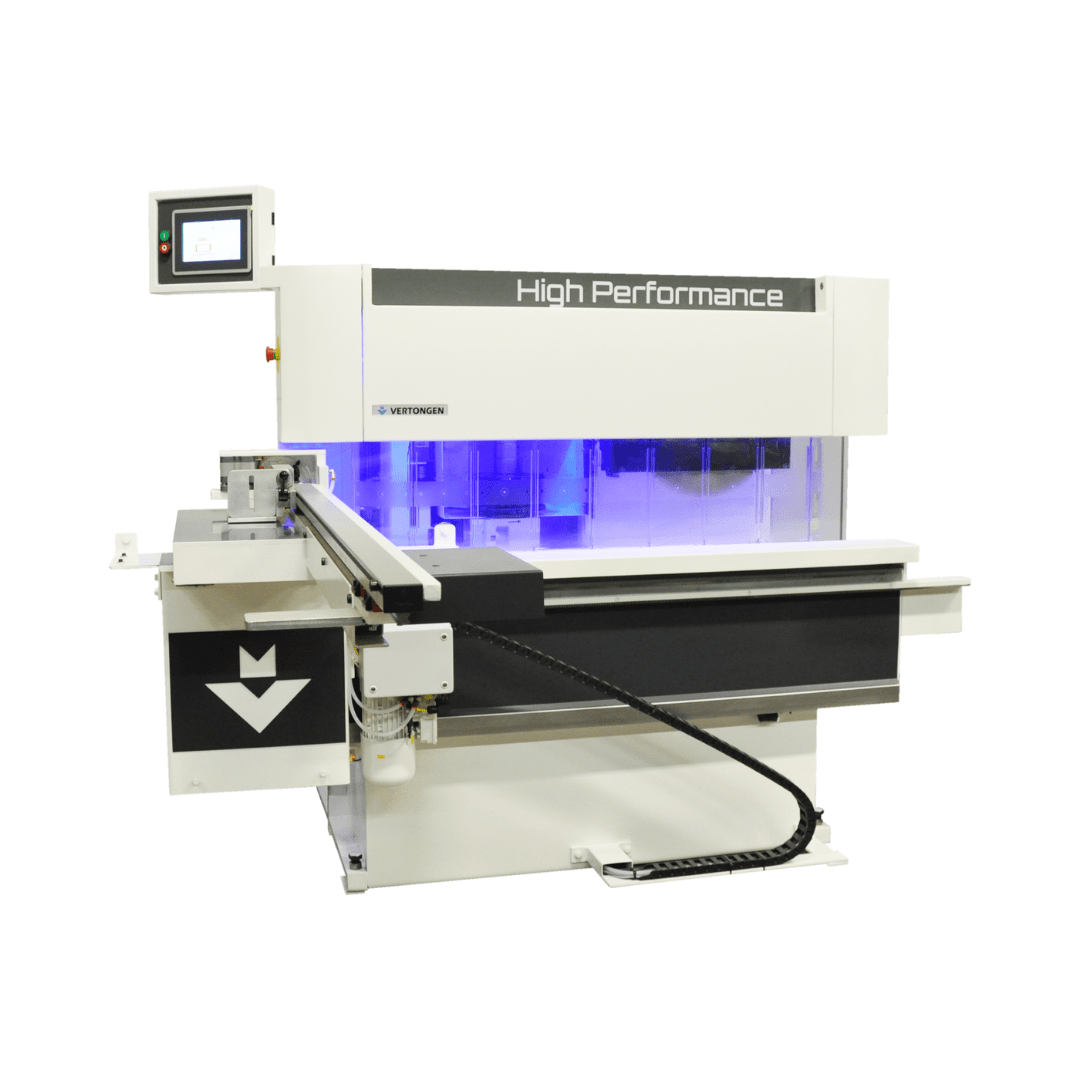

Upgrade your Pentho Compact 3 with our High-Performance pack

Pentho Compact 4

The Pentho Compact 4 is our advanced tenoner. It operates manually and has 2 vertical Prolock spindles of 200 mm. This allows you to make a complete window to size without any tool changes.

- All movements are manual adjustable

- 7” touch panel for starting motors and job recipes in own language

- Total table swiveling +60° / -60°

- Round backing wood available

- Digital length-fence 2.4 with 1 swiveling backstop

- High-quality saw and tenon heads installed

Turn your setup time into valuable production time

Upgrade your Pentho Compact 4 with a High-Performance Pack, to get a fully CNC-automated tenoner.

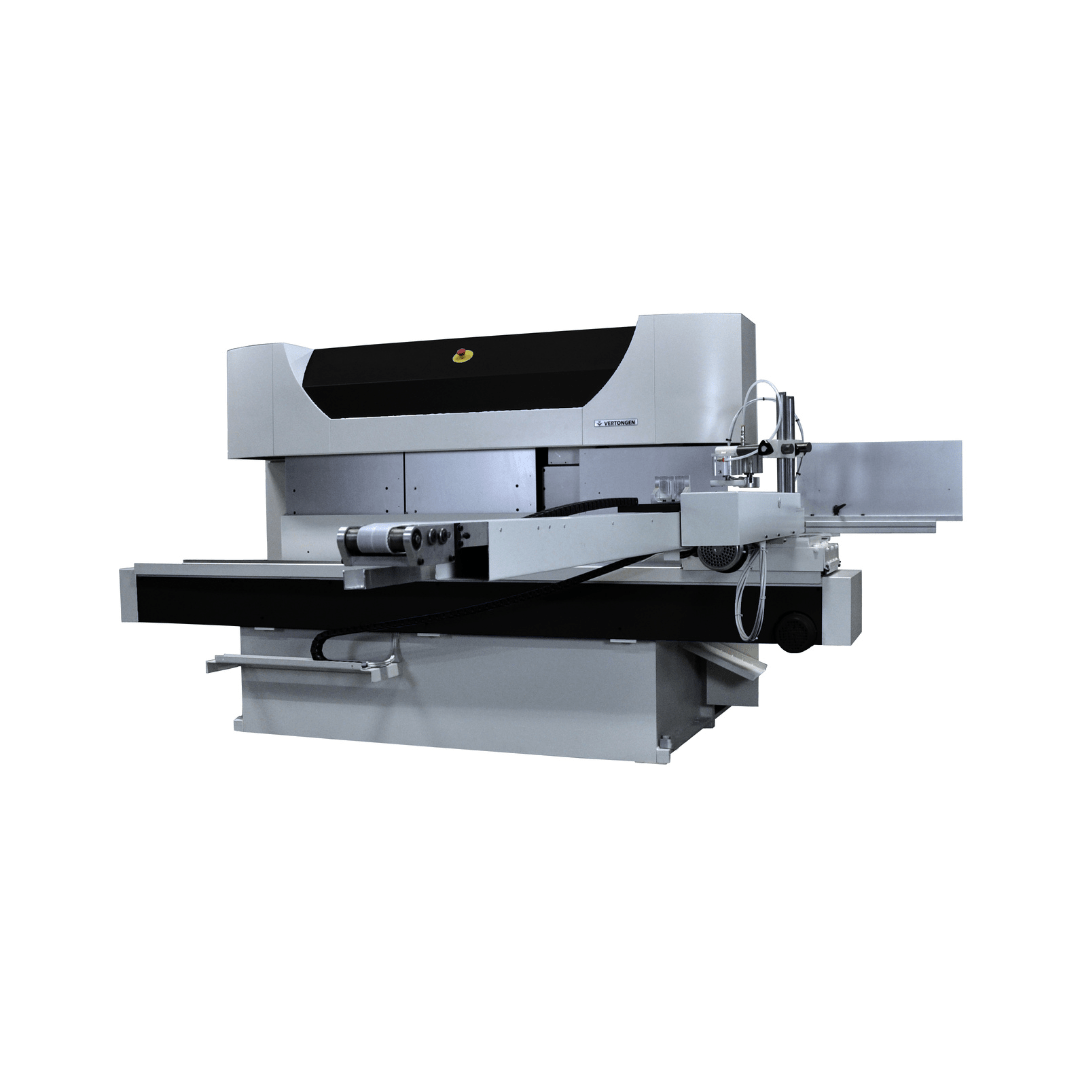

Pentho Control

The Pentho Control is produced with one or more vertical spindles and a noise-reduced cut-off saw. All spindles and features can be combined with each other.

- 7″ touch panel in own language

- Composition depending on customer needs

- Total project followed by Vertongen

- CNC available on every movement

- Combinable with profile moulder

- Online communication available

Pentho Compact Kitchen

The Pentho Compact Kitchen is our smart tenoner. Its spindle is designed to stack tools. Allowing you to size and cope your rails and stiles without manual setup between different profiles.

- Saw with a cut-off capacity of 1.25″

- 1 x Vertical spindle 300 mm with Prolock

- 7” touch panel for starting motors and job recipes in own language

What our customers say about us:

Find a Vertongen dealer

Vertongen is a Belgium-based company with distributors all over the world. All of them are knowledgeable about the operation and use of our machines.

Want to know more about Vertongen, our machines, how they work, and how to implement them into your operations?

Contact us and get ready to revolutionize your production process or contact a local supplier.