Upgrades Available

Upgrades Available Pentho Compact 4

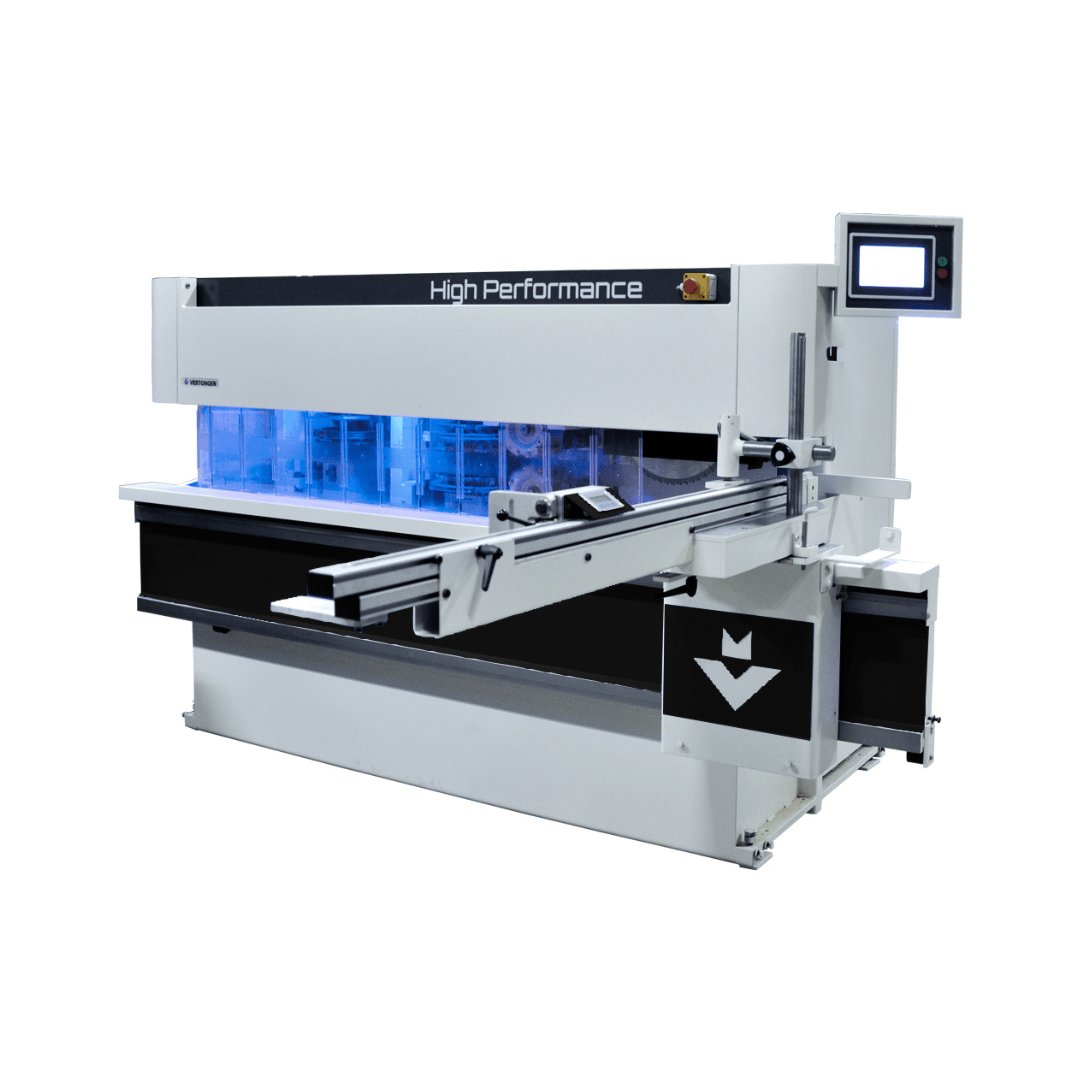

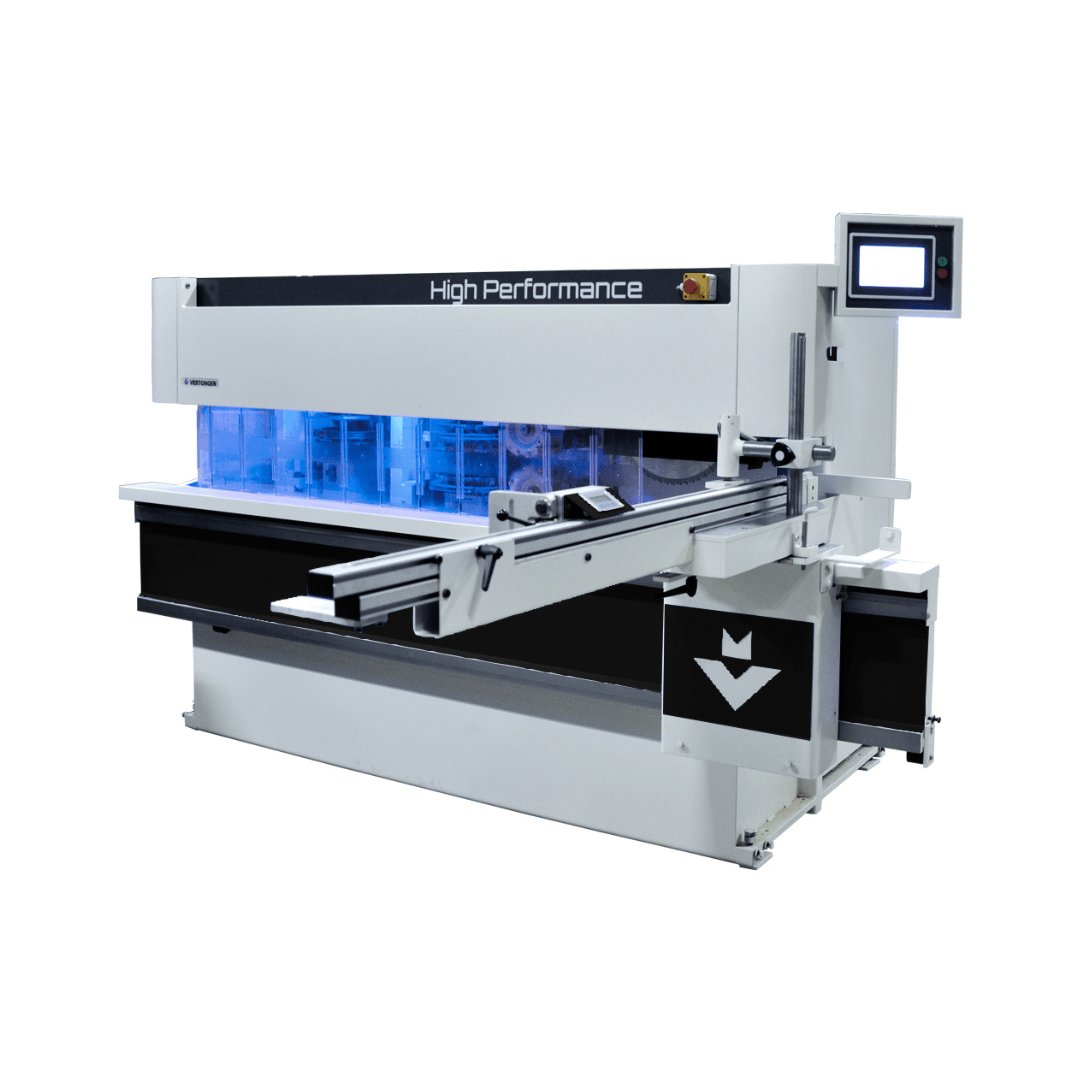

The Pentho Compact 4 is a slot and tenon machine for making professional woodworking (corner) joints.

- Saw with cut-off capacity 150 mm

- Tenon heads

- 2 x Vertical spindle 200 mm with Prolock

- Performance en high-performance pack available

- All movements are manually adjustable

- 7-inch touch panel for starting motors and job recipes in own language

- Total table swiveling +60° to -60°

- Round backing wood available

- Digital length-fence 2,4 with 1 large swiveling backstop

- High-quality saw and tenon heads installed

The Pentho Compact 4 has a noise-reduced cut-off saw with a cut-off capacity of 150mm, two tenon heads and 2 vertical spindles adjustable to an accuracy of 0.1 mm.

The slot & tenon machine is equipped with a robust table on a stable and wear-resistant vertical slide bar. For angled work, the table can be swiveled 60° in two directions.

As a safety system, the Pentho Compact 4 is equipped with a transparent dust protection screen that moves with the table and completely seals the machine.

Upgrade your Pentho Compact 4 with our High-Performance pack.

Convert your set-up time into valuable production time.

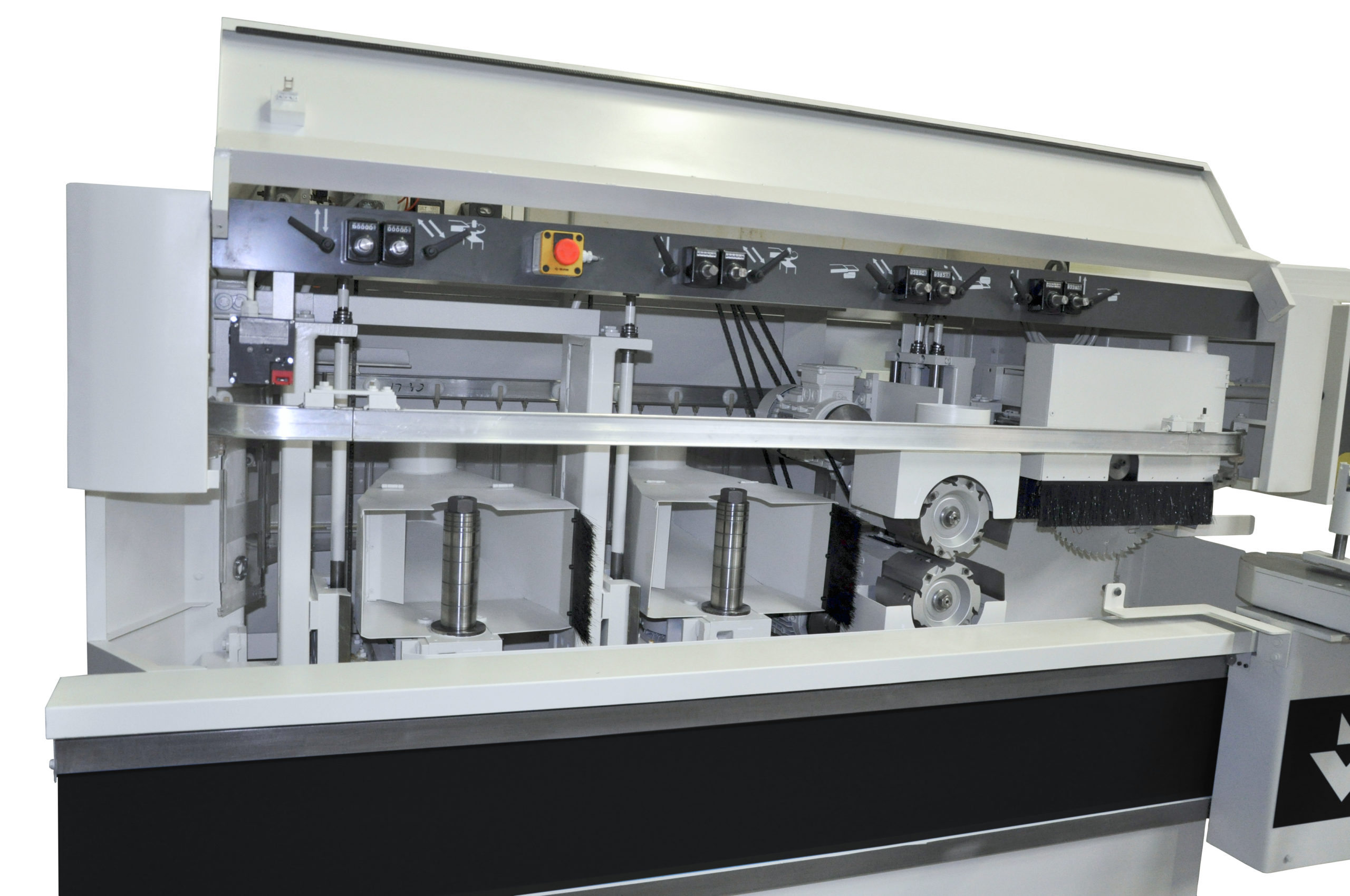

With 2 spindles of 300 mm and 9 individual CNC positionings, this High-Performance CNC-tenoner switches between different programs in only 15 seconds. All axes, including the saw, set themselves simultaneously and automatically in the correct position. The position of the length-fence gets automatically recalculated in function of the saw. And its easy, straightforward graphical application allows the operator to make any type of single tenon right from the first time.

Technical product specifications

General

- 7" touch panel:

- Operate the machine and select motors

- Security:

- Conform CE

- Dimensions:

- 2730 x 1700 x 1600 mm

- Total Extraction:

- 1 x Ø 80 mm; 4 x Ø 150 mm

Table

- Table mounting:

- Vertical attached, extra solid

- Movement:

- Manual with automatic movement option

- Table:

- Fixed in height, Swiveling +60° to -60°

- Backing wood:

- Clamp for straight backing wood, with round backing wood option

- Clamps:

- Manual vertical clamping, with vertical pneumatic clamps option

- Length fence:

- 2,4m with 3,4m and automatic length-fence option

- Dimensions:

- 160mm x 600mm

Cut-off saw

- Motor:

- 2,2 kW - 3000 tpm

- Adjustment:

- Horizontal 20-155mm, with 150mm cut-off capacity

- Noise reduced saw:

- Ø 400mm, included

- Extraction:

- Ø 80mm

- Positioning:

- Manual on side bearings

- Measuring rod:

- Mechanical, digital read-out, or laser option

Tenoning heads

- Motor :

- 2 x 2,2 kW

- RPM :

- 4500

- Suspension:

- Side bearings

- Reading:

- Mechanical digital counter on front and rear side of the machine

- Tenon heads:

- Included, Ø 160mm, length 145mm, with exchangeable blades

- Extraction:

- 2 x Ø 150mm

- Movement:

- Horizontal upper -55mm to +25mm

Horizontal lower -55mm to 0mm

Vertical upper +3mm to +150mm

Vertical lower -2mm to +80mm

Vertical spindles

- Motor:

- 7,5 kW

- RPM:

- 4000

- Suspension:

- Dovetailed

- Reading:

- Mechanical digital counter on front and rear side of the machine

- Movement:

- Horizontally 150mm, vertically -150mm to +25mm

- Measurements spindle :

- Length: 200mm with Prolock, 300mm x 50mm with HP Prolock

Diameter: Ø 40mm or Ø 50mm - Tool Ø:

- Maximum Ø 350mm

- Extraction:

- 150 mm Ø

You may also be interested in

Pentho Compact 3

The Pentho Compact 3 is our universal tenoner. It has a noise-reduced cut-off saw, two tenon heads and a vertical Prolock spindle adjustable to an accuracy of 0.1 mm.

- All movements are manual adjustable

- 7” touch panel for starting motors and job recipes in own language

- Total table swiveling +60° / -60°

- Round backing wood available

- Digital length-fence 2.4 with 1 swiveling backstop

- High-quality saw and tenon heads installed

Convert your set-up time into valuable production time

Upgrade your Pentho Compact 3 with our High-Performance pack

Please fill out the form below and you will receive a link via email to download our brochure.

Find a Vertongen dealer

Vertongen is a Belgium-based company with distributors all over the world. All of them are knowledgeable about the operation and use of our machines.

Want to know more about Vertongen, our machines, how they work, and how to implement them into your operations?

Contact us and get ready to revolutionize your production process or contact a local supplier.