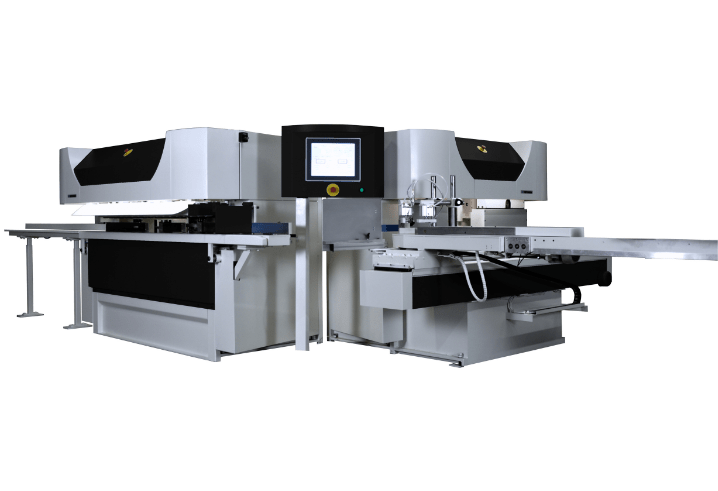

Profil Compact 2

The advanced Profil Compact 2 moulder is produced with 2 spindles without top bearing.

- 2 Vertical spindles 300mm with Prolock

- Profiling height up to 140mm

- 7 inch touch panel in own language

- First spindle can jump in and out to avoid breakout during storm proofing

- Both spindles can turn left and right

- Automatic stormproof cycles

- All tools for one product type can be installed

- Easy tool changeover for different product

- Integrated feeding device; CNC available

The advanced Profil Compact 2 moulder is produced with 2 spindles without top bearing.

All tools for one product type can be installed at the same time, with easy change over for another product type. The 2 spindle profile moulder is a complete application so no further options are available. With the jump-head, storm proofing can be done without breakout. All operations can be controlled by the 7” touch-screen panel with an intuitive interface.

Technical product specifications

General

- 7 inch touch panel:

- Operate the machine and select motors

- Construction:

- Combined self-supporting frame with a cage construction

- Security:

- Conform CE

Table

- Guiding:

- 80mm high, 1st fence is manually adjustable

- Through feed:

- Air jets in table for better through feed of timber

- Cleaning:

- Compressed air system between table and fence

- Width:

- 160mm

- Extension table:

- for storm proofing

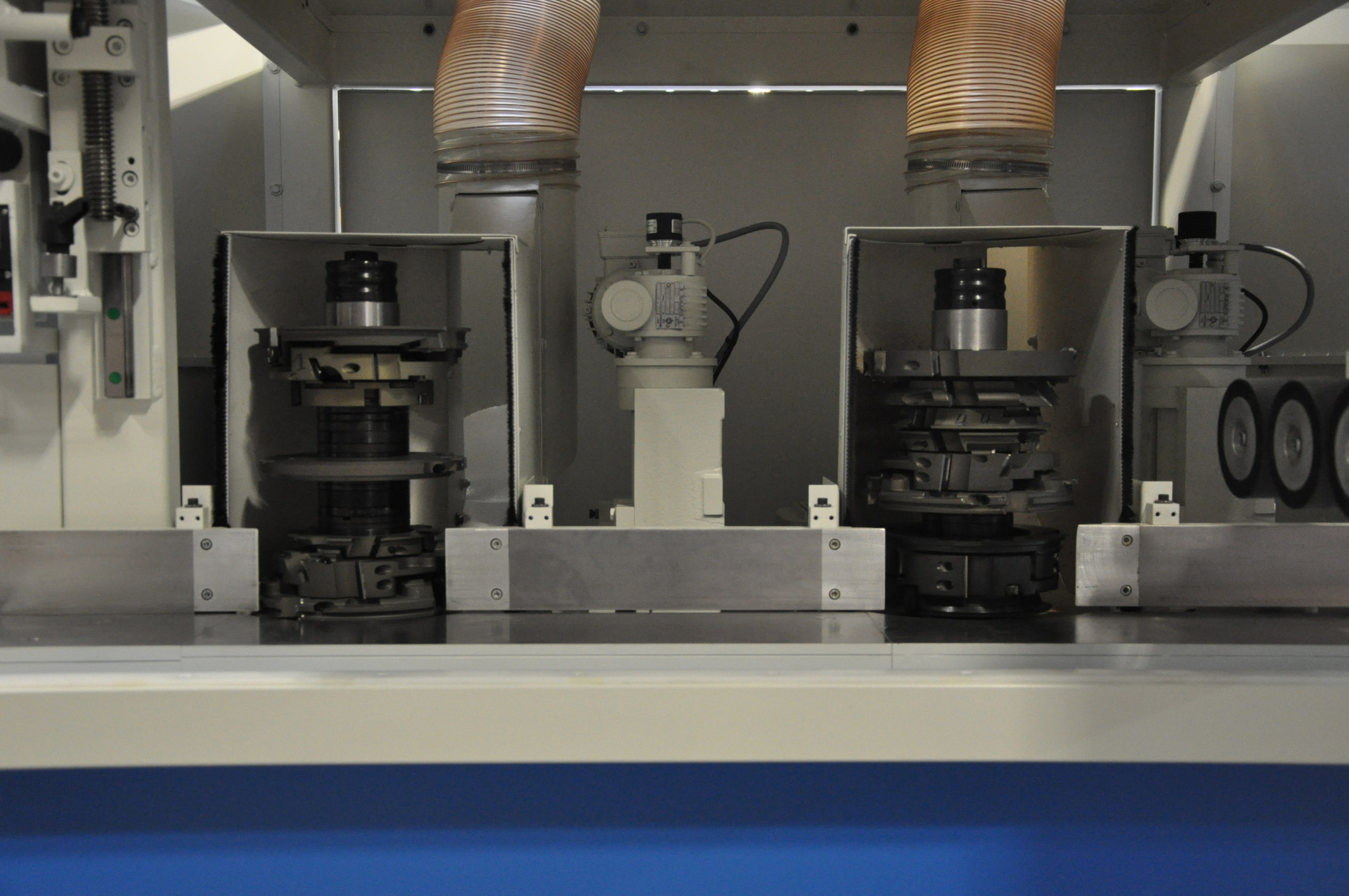

Vertical spindle 1

- Motor:

- 7,5 kW

- RPM:

- 6000 tpm

- Suspension:

- Dovetailed

- Positioning:

- Vertical CNC-positioned with ball circulating screw

Horizontal CNC-positioned option with ball circulating screw - Turning direction:

- Left and right

- Spindle:

- 300mm with Prolock, Ø 50mm

- Tool Ø:

- Minimum zero Ø 120mm

Maximum Ø = zero Ø + 90mm, max. 240mm - Extraction:

- Ø 180mm

Vertical spindle 2

- Motor:

- 7,5 kW

- RPM:

- 6000 tpm

- Suspension:

- Dovetailed

- Positioning:

- Vertical CNC-positioned with ball circulating screw

Horizontal fix - Turning direction:

- Left and right

- Spindle:

- 300mm with Prolock, Ø 50mm

- Tool Ø:

- Minimum zero Ø 120mm

Maximum Ø = zero Ø + 90mm, max. 240mm - Extraction:

- Ø 180mm

Feeding device

- Speed:

- Adjustable between 2 - 12 m/min

- Vertical:

- 20mm to 140mm

- Rollers:

- 13 rollers, Ø 100 mm, every 103 mm

- Positioning:

- CNC-positioned

You may also be interested in

Profil Control

The Profil Control is produced with one or more spindles.

- 7″ touch panel in own language

- Composition depending on customer needs

- Total project followed by Vertongen

- CNC available on every movement

- Combinable with tenoner

- Online communication available

PenPro Control

The Penpro Control is a fully CNC-controlled combination of the Pentho Control and the Profil Control.

- One-man operation

- Production capacity of more than 400 parts each shift

- 15″ touch panel in own language

- Mounting of the tools and presetting the machine done by Vertongen

- Total project followed by Vertongen

Please fill out the form below and you will receive a link via email to download our brochure.

Find a Vertongen dealer

Vertongen is a Belgium-based company with distributors all over the world. All of them are knowledgeable about the operation and use of our machines.

Want to know more about Vertongen, our machines, how they work, and how to implement them into your operations?

Contact us and get ready to revolutionize your production process or contact a local supplier.